Research Topics

Fracture mechanics of soft materials

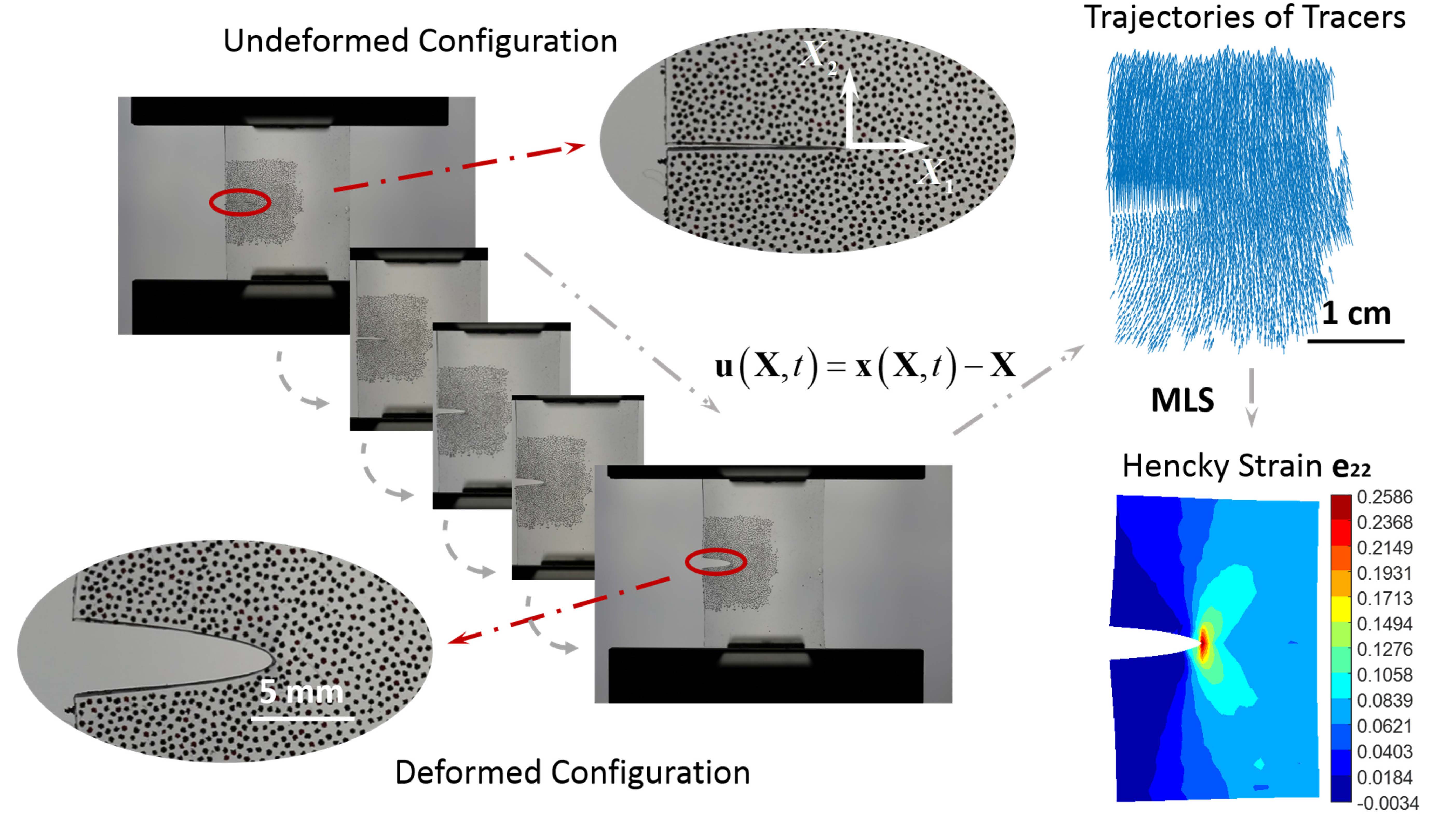

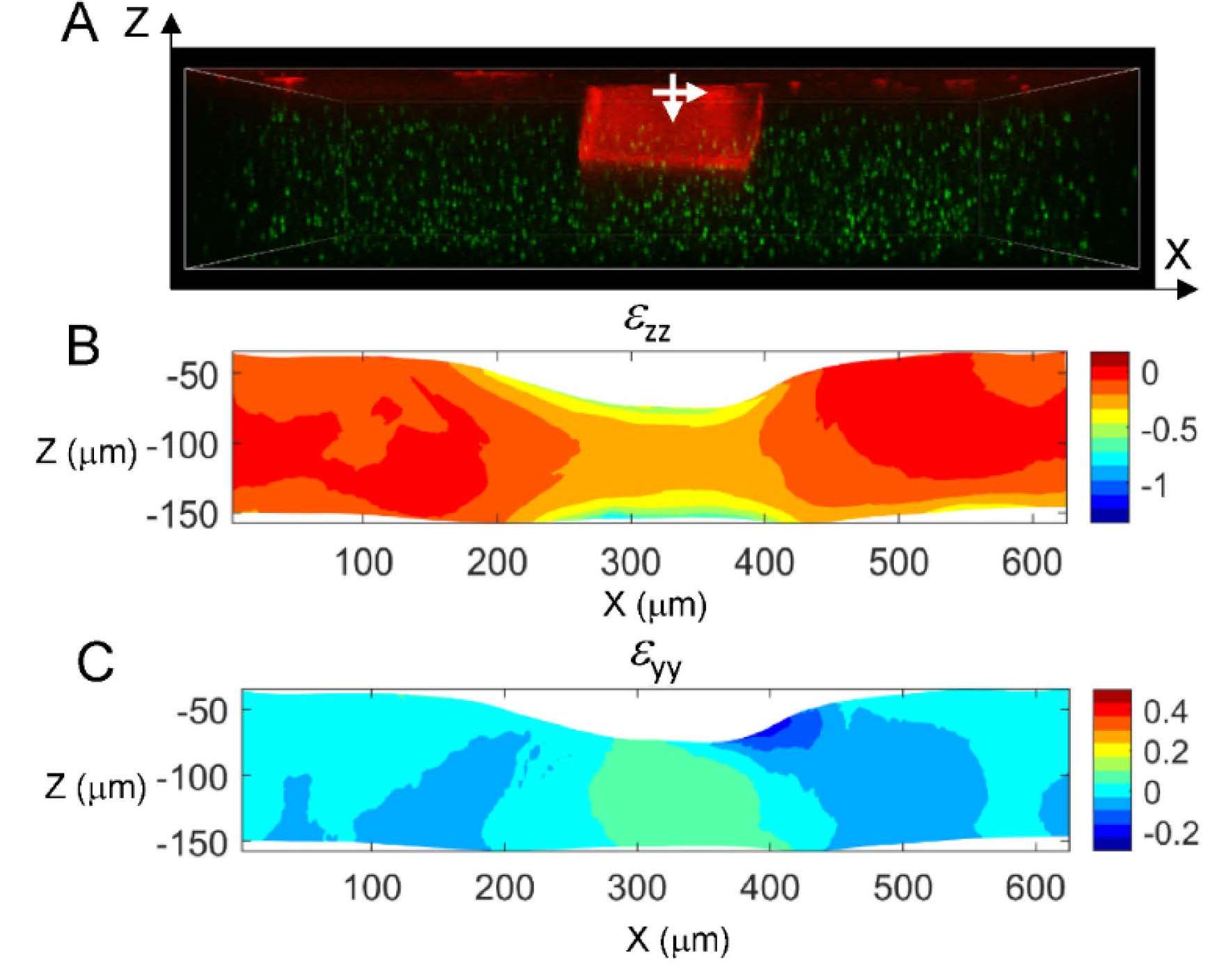

The ability of soft materials to sustain mechanical stress and to resist fracture is important for the reliability of soft material based devices. The fracture mechanics of soft materials has received much less attention than traditional stiff materials such as metal and ceramics. Soft materials exhibit unique fracture behaviors that cannot be described by classical fracture mechanics theory due to the inherent nonlinearity associated with finite deformation. Typically macroscopic fracture results from the growth of small defects. There is a limited understanding on how stresses near the defects in soft materials interact with material property and microstructure to produce local failure. To answer this question, we are developing imaging method to experimentally measure the deformation fields in the vicinity of defects in soft materials. We also combine the experimental findings with theoretical and computational analyses in order to understand how fracture behaviors are related to material property, and ultimately to identify principles to engineer tough soft materials.

Contact, adhesion and friction

In most adhesion systems, mechanical deformation of the adhesive material provides the driving force for the separation of interfaces. The effect of material deformation on the separation process depends on material property, interfacial slip and surface topography. In this regard, mechanics plays a crucial role in controlling adhesion strength. For example, an important problem that remains poorly understood is the effect of material viscoelasticity and interfacial friction on adhesion strength. We are building computational models to simulate detachment of viscoelastic adhesive materials from flat rigid surfaces, aiming to understand how the viscous dissipation contributes to the overall adhesion strength, and then we will extend the model to include effects of interfacial slip, material heterogeneity and surface topography.

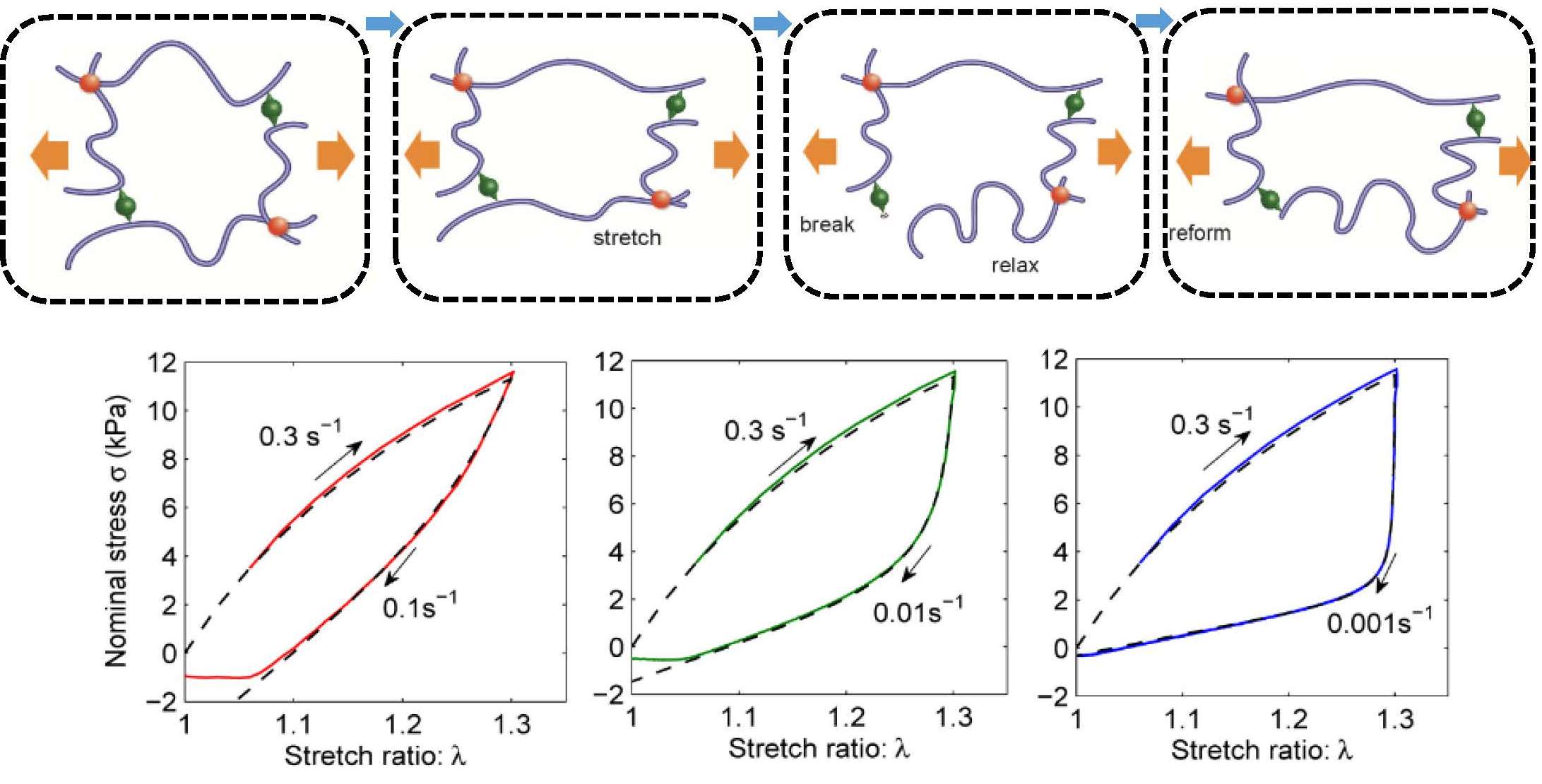

Continuum mechanics of soft polymers

Soft polymers and gels have emerged as an exciting class of materials due to their high deformability, bio-compatibility and responsiveness to various external stimuli. They have been widely applied in areas including stretchable electronics, pressure sensitive adhesives, biomedical implants, and actuators with large shape change. They are also promising for the next generation of soft robotics. Mechanical deformation of soft materials is complicated because of the nonlinearities due to large deformation and the couplings with multiple physical phenomena such as heat conduction, light propagation, and chemical reaction. We are developing continuum mechanics models for various novel soft material systems, and will implement these models in computational software, which will allow simulations for complex geometry and loading conditions, an essential step to facilitate future technological applications. Examples of the materials include polymers with photo-activated or thermally-activated dynamic bonds.

Biomechanics

We are also interested in developing quantitative models for the mechanics of biological cells and other soft biomaterials. Currently we are collaborating with Prof. Jianyu Li at McGill University on hydrogel-based bioadhesives.

Sponsors

We are grateful to the following funding sponsors: